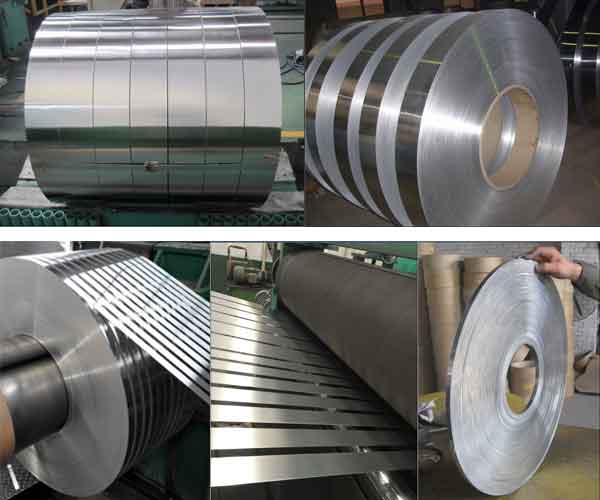

Aluminium strip and Aluminium sheet for heat exchangers

In our rolling mills, we produce Aluminium strip and Aluminium sheet for heat exchangers which overcome every challenge with ease - be it for heating, ventilation or refrigeration, or to keep mobility well tempered.

Aluminium strip and Aluminium sheet for heat exchangers can be readily brazed and combine light weight and strength with good workability. The material's resistance to corrosion, its ability to conduct heat and the fact that it is easily recycled are also key strengths in this application.

Key features

- Good thermal and electrical conductor

- Corrosion resistant.

- Lightweight and strong

- Numerous surface functions and treatments

- Good welding and adhesive bonding properties

- Recycable

In mechanically joined heat exchangers, high formability is essential to the trouble-free production of collar fins. We supply unclad materials like EN AW-1050, EN AW-1100, EN AW-1200, EN-AW 8006 or EN AW-8011, the production of which is tailored to meet this highly exacting requirement in fin forming.

Aluminium strip details

| Alloy | Temper | Thickness(mm) | Tolerance(mm) | Clad ratio(%) | Mechanicalproperty | Application | ||

|---|---|---|---|---|---|---|---|---|

| Tensile>strength | Yield strength | Elongation | ||||||

| σb(MPa) | σp0.2(Mpa) | δ(%)min | ||||||

| 3003 | H14 | 0.08~0.12 | ±0.005 | >None | 150~200 | ≥120 | 1 | Evaporator fin and plate |

| 3003 | H26 | 0.3~0.35 | ±0.015 | None | 190~220 | ≥160 | 8 | Glass mounting bracket material |

| 3003 | H14 | 0.06~0.1 | ±0.005 | None | 150~200 | ≥120 | 1 | Radiator fin and plate |

| 4343/3003/ 4343 | H14 | 0.06~0.1 | ±0.005 | 8~12 | 150~200 | ≥120 | 1 | |

| 4343/3003/ 4343 | H14 | 0.08~0.12 | ±0.005 | 8~12 | 150~200 | ≥120 | 1 | Parallel condenser fin |

| 4343/3003/ 4343 | H14 | 0.1~0.12 | ±0.005 | 8~12 | 150~200 | ≥120 | 1 | Charge air cooler material |

| 4045/3003/ 4045 | H14 | 0.1~0.12 | ±0.005 | 8~12 | 150~200 | ≥120 | 1 | |

| 1060 | O | 0.35~0.4 | ±0.02 | None | 55~95 | ≥15 | 25 | Air cooling fin material for tubes |

| 1100 | O | 0.35~0.4 | ±0.02 | None | 75~105 | ≥25 | 25 | |

| 3003 | O | 0.2~0.3 | ±0.01 | None | 100~150 | ≥45 | 15 | Aluminum for heating element |

| 3003 | H16 | 0.5~0.7 | ±0.02 | None | 150~210 | ≥120 | 1 | |

| 4047 | H18 | 0.05~0.1 | ±0.005 | None | ≥200 | ≥170 | 0.5 | |

| 4A13 | H18 | 0.05~0.1 | ±0.005 | None | ≥190 | ≥16 | 0.5 | |

| 4104 | H18 | 0.05~0.1 | ±0.005 | None | ≥220 | ≥190 | 0.5 | |

| 3003(inner fin) | O | 0.2~0.3 | ±0.007 | None | 100~150 | ≥45 | 15 | Oil cooler |

| 6951(inner fin) | O | 0.2~0.3 | ±0.007 | None | 115~165 | ≥50 | 15 | |

| 3003(external fin) | H14 | 0.1~0.15 | ±0.005 | None | 150~200 | ≥120 | 1 | |

| 3003(inner fin) | O | 0.2~0.3 | ±0.007 | None | 100~150 | ≥45 | 15 | Engineering machinery |

| 3003(inner fin) | H12 | 0.2~0.3 | ±0.007 | None | 120~160 | ≥85 | 2 | |

| 3003(external fin) | H14 | 0.1~0.15 | ±0.005 | None | 150~200 | ≥120 | 1 | |

Performance index of Aluminium sheet material

| Alloy | Temper | Thickness(mm) | Tolerance(mm) | Clad ratio(%) | Mechanicalproperty | Application | ||

|---|---|---|---|---|---|---|---|---|

| Tensile>strength | Yield strength | Elongation | ||||||

| σb(MPa) | σp0.2(Mpa) | δ(%)min | ||||||

| 4343/3003 | O | 1.2~3 | ±0.03 | 5~10 | 100~150 | ≥45 | 25 | Radiator fin and plate |

| 4343/3003/ 7072 | O | 1.2~3 | ±0.03 | 5~10 | 100~150 | ≥45 | 25 | |

| 4343/3003/4343 | O | 0.4~0.5 | ±0.02 | 8~12 | 100~150 | ≥45 | 27 | Evaporator fin and plate |

| 4045/3003/4045 | O | 0.8~1.2 | ±0.03 | 8~12 | 100~150 | ≥45 | 27 | |

| 4045/3003/ 4045 | O | 2~3 | ±0.05 | 8~12 | 100~150 | ≥45 | 25 | Charge air cooler material |

| 4045/3003/ 4045 | O | 0.5~0.8 | ±0.02 | 15~20, 10~15 | 100~150 | ≥45 | 25 | Oil cooler |

| 4104/3003/ 4104 | O | 0.5~0.8 | ±0.02 | 15~20, 10~15 | 100~150 | ≥45 | 25 | |

| 4104/3003/ 4104 | H14 | 0.6~0.8, 1.2~1.5 |

±0.02, ±0.03 |

13~17, 8~12 | 150~200 | ≥120 | 3 | Engineering machinery |

Key features

- Aluminium strip is impermeable to light and gas, it can be easily formed and it combines well with other materials.

- We supply plain as well as lacquered strip and sheet made from alloyed aluminium in thicknesses ranging from 0.180 to 0.250 mm.

- This high quality material can be used in conjunction with a wide range of lacquering systems to create functional and well-styled solutions for the catering industry and for domestic purposes.